Administration of truck driving schools will gain three advantages by using truck simulator within their programs:

1. Cost efficiency

2. Elimination of the training yard

3. Quality-controlled training standards

1. Cost efficiency

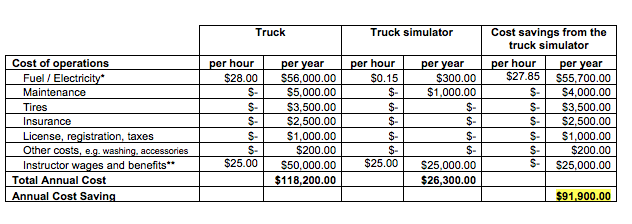

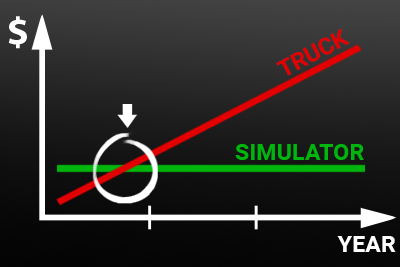

The simple fact is that compared to a real truck, operating costs for truck simulators are remarkably low. . This means that you generate substantial savings every hour you train with a simulator instead of a truck. When you calculate the “payback period”, how long it takes in months or years, to earn back your investment, you will find that your new simulator can pay by itself in less than one year.

The following is a sample calculation based on an average of real operating costs provided by our customer and an independent study, Fender et al. (2012)1

* Based on 2,000 training hours per year

**Using the truck simulator 50% in self-paced mode

1. Fender, K. J. and Pierce, D. A. (2013). An Analysis of the Operational Costs of Trucking: 2013 Update. American Transportation Research Institute. St.Paul, Minnesota

Do yourself a favor and try the exercise using your own costs. Download the following Excel spreadsheet (Cost comparison Sim vs Truck) and enter your own numbers in the blue cells. You may find the results too good to be true, but numbers don’t lie.

2. Eliminate the Training Yard

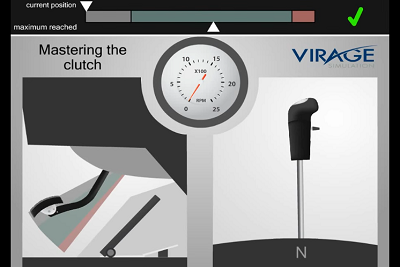

Traditionally, basic maneuvers like shifting and backing were practiced exclusively in training yards. Today, truck simulators are replacing many training yards. Research shows that, compared to learning in a truck, students learn basic maneuvers with the Golden ShifterTM, Golden MirrorsTM and Golden SteeringTM truck simulator training programs with equal or greater efficiency, i.e. one hour of training on the simulator can be equal to two or two and a half hours of training in the truck. This allows administrators to eliminate their training yards and avoid paying all related expenses (rent or mortgage, taxes, insurance, maintenance, security etc.) by acquiring the VS600M truck driving simulator and the Golden Training programs.

3. Quality-controlled training standards

Quality control is basic to improving profits and quality control in training requires objective, reliable driver performance measures. The VS600M truck driving simulator, Golden Programs and Driver Tracker SystemTM are designed to improve driver training standards by allowing you to:

- Apply concepts from theory class that are too expensive or too dangerous to train in a real truck

- Facilitate delivery of a comprehensive and structured training program with standardized lessons

- Administer objective driver evaluations and compare individual performance scores over time and against group averages using the Student Tracker

- Help slower learners progress faster by using performance-based-practice (PbP) exercises

- Identify best-practices in teaching to be demonstrated and shared with other trainers