INTRODUCTION

Over the past several decades, simulators have become popular in many fields as a means of teaching complex or advanced skills. Using a simulator, skills can be practiced in an environment that is safe, allowing the student to learn from errors without negative real-life consequences. The student can quickly gain experience with repeated trials in scenarios that can be manipulated by the trainer to simulate various hazardous or complicated situations. This allows the student to quickly learn how to master higher order skills such as scanning their environment more effectively, handling higher workloads, identifying critical information and making better decisions quickly.

Based on the long-established and successful application of simulator-based training in the aviation industry, researchers have investigated the application of simulator based training for drivers (Blickensderfer et al., 2005; Pradhan, Pollatsek, Knodler, & Fisher, 2009; Romoser & Fisher, 2009; Pollatsek, Romoser & Fisher, 2012).

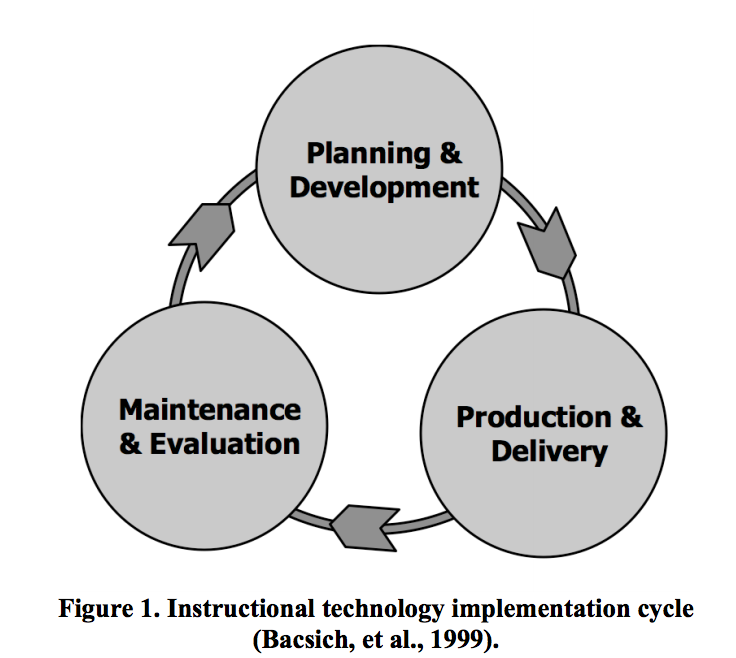

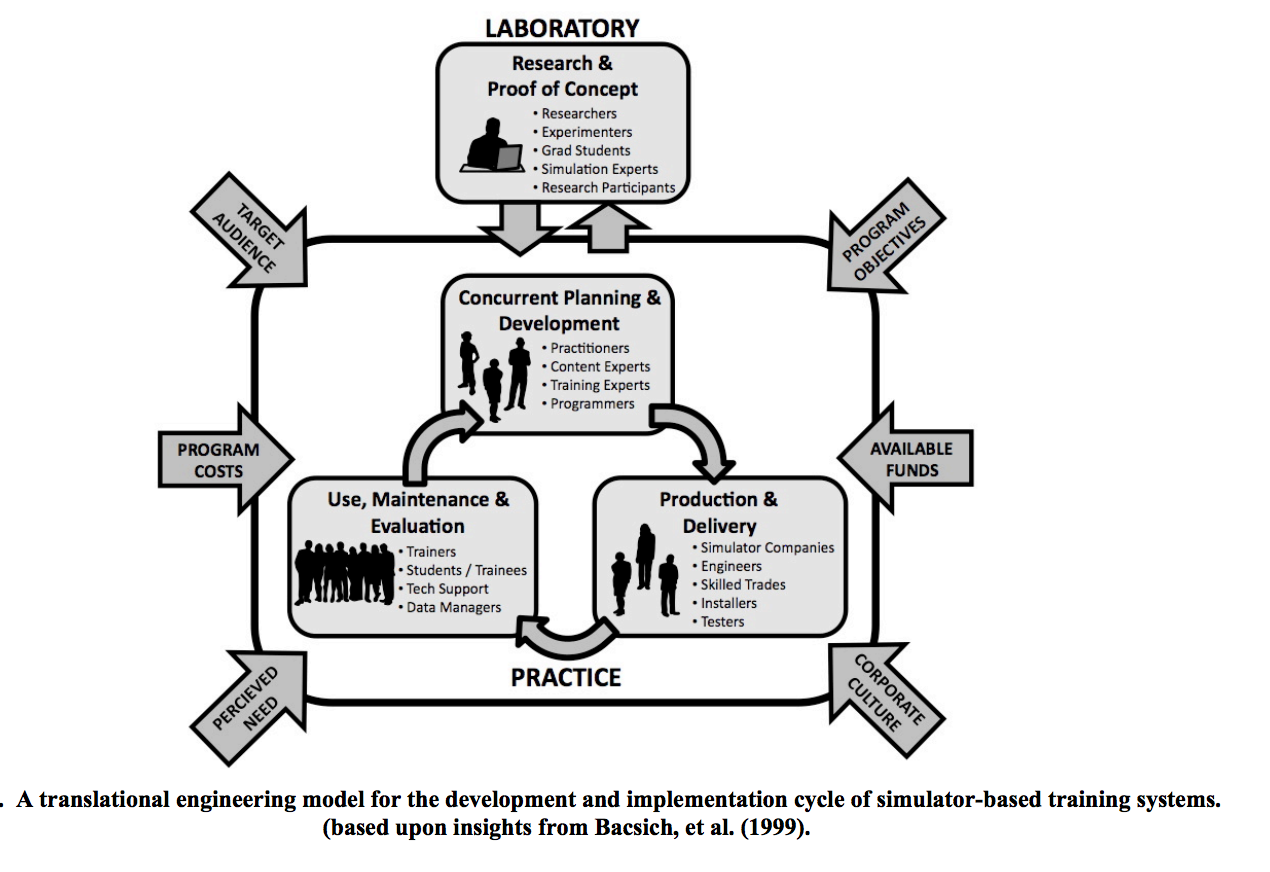

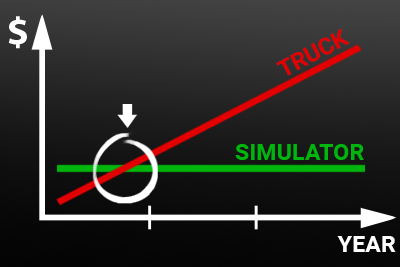

Many administrators of truck training centers have considered and some have tried using truck simulators in their operations. However, the majority of truck driver training centers still operate without simulators. One potential reason for this is that the technology has not been implemented correctly. The successful transition from the academic or simulator company research laboratory to real life is rarely as easy as shipping the simulator from the lab and to the practitioner. Often the technology that was developed and tested in the lab is not immediately suitable for use or the end users are insufficiently trained to operate the simulator or understand the data it collects Before simulation technology can be translated for use in practice, careful consideration must be given to contextual factors such as the goals of the organization, the expectations and expertise of the users, the operating budget, the environment the simulators will be used

in, and how performance data will be utilized.